Description

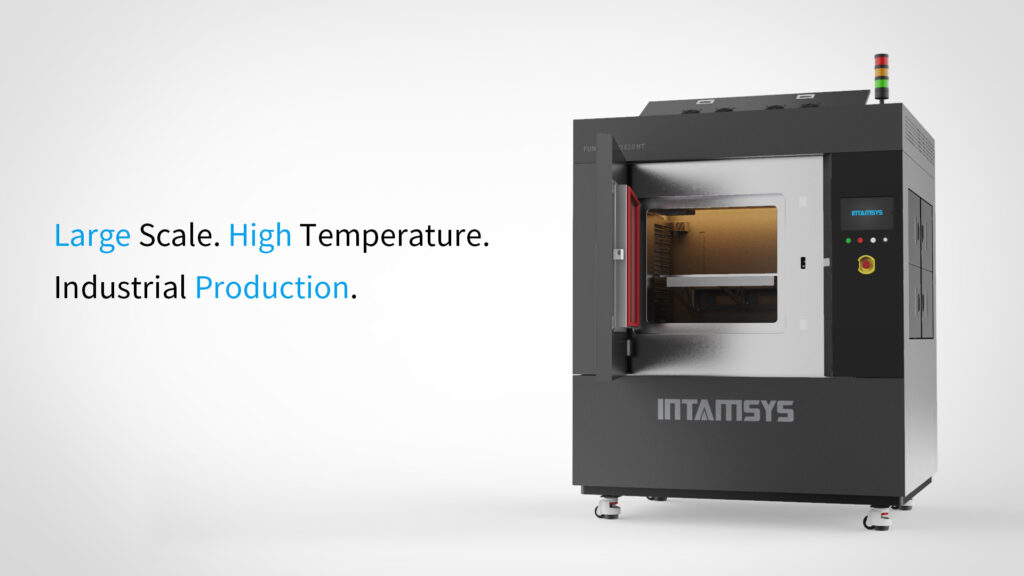

The Next-Generation in Large Scale FFF Printing

Your Path to Production

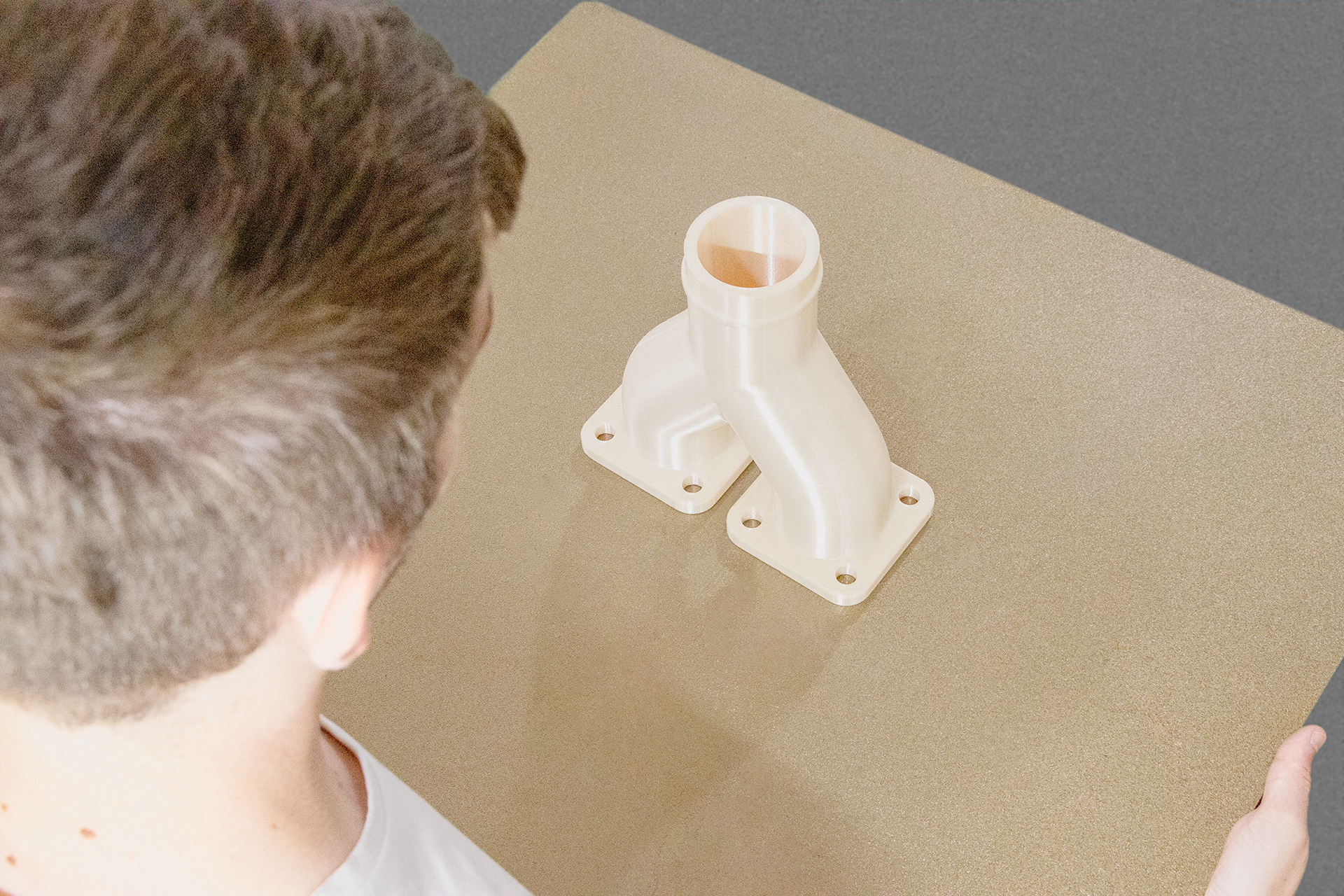

Industrial 3D printing technology enables customers to print functional prototypes, tooling and

end-use parts that optimize the entire design to the manufacturing process. 3D printing technology

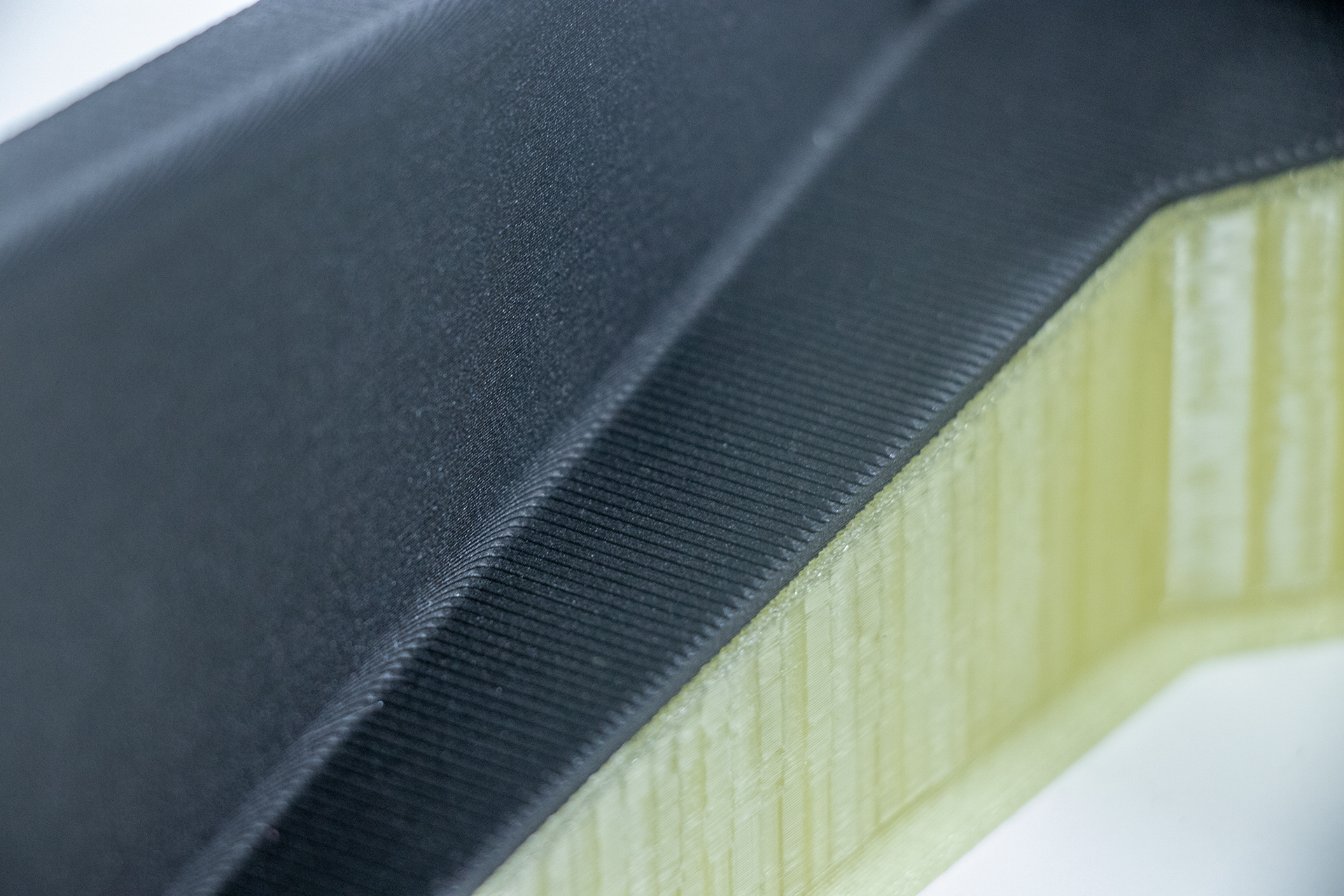

has enabled customers to print end-use parts that are both lighter and stronger while creating

tools that have pushed the boundaries of industrial applications. Aerospace and automotive have

been huge benefactors of 3D printing as well as early adopters of the end-use capabilities that 3D

printing now provides.

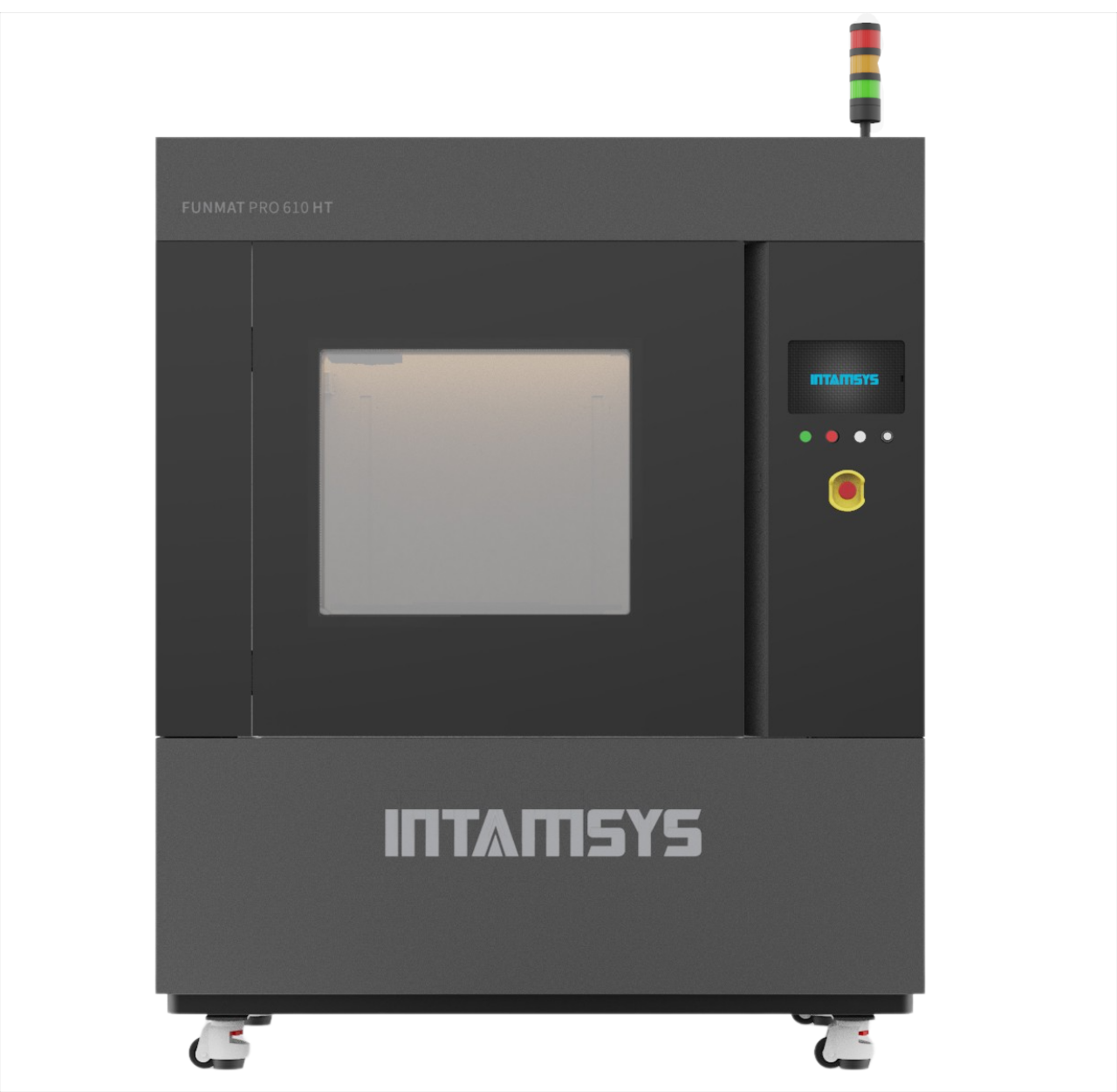

INTAMSYS has paved a way with their breakthrough FUNMAT PRO 610 HT. Unlocking the potential

of industrial-grade, high-quality 3D printing, equipped to effectively handle the tough

requirements needed to print with high-performance thermoplastics.

No products in the cart.

No products in the cart.